Difference Between Squirrel Cage And Wound Rotor Induction Motor Pdf

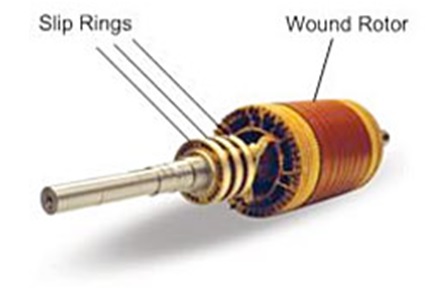

Squirrel Cage Induction Motor vs Slip Ring Induction Motor Comparison of Squirrel cage induction motor with slip ring induction motor (Wound Rotor Induction Motor) is listed in the below table: Squirrel Cage Induction Motor Slip ring (wound rotor) Induction Motor In Squirrel cage induction motors the rotor is simplest and most rugged in construction In slip ring induction motors the rotor is wound type. In the motor the slip rings, brushes are provided. Compared to squirrel cage rotor the rotor construction is not simple. Cylindrical laminated core rotor with heavy bars or copper or aluminium or alloys are used for conductors. Cylindrical laminated core rotor is wound for as the number of poles of the stator.

Rotor conductors or rotor bars are short circuited with end rings. At starting the 3 phase windings are connected to a star connected rheostat and during running condition, the windings is short circuited at the slip rings. Rotor bars are permanently short circuited and hence it is not possible to connect external resistance in the circuit in series with the rotor conductors.

Both squirrel cage and wound-rotor, and induced current flows. • The difference between the motor speed. –Induction motor: voltage applied to the stator. Free black ops 2 nuketown 2025 code.

It is possible to insert additional resistance in the rotor circuit. Therefore it is possible to increase the torque ( the additional series resistance is used for starting purposes) Cheaper cost Cost is slightly higher. No moving contacts in the rotor. Carbon brushes, slip rings etc are provided in the rotor circuit.

Higher efficiency. Comparatively less efficiency. Low starting torque. It is 1.5 time full load torque.

High starting torque. It can be obtained by adding external resistance in the rotor circuit. Speed control by rotor resistance is not possible.

Speed control by rotor resistance is possible. Starting current is 5 to 7 times the full load.

Less starting current. Advantages of Squirrel-Cage Induction Motors The advantages of squirrel-cage motors compared with the slip ring induction motors are given below (i) They are more robust and cheaper (ii) Comparatively they have higher efficiency and power factor (iii) Since the risk of sparking is eliminated by the absence of slip rings and brushes, they are explosion-proof. Advantages of Slip ring Induction Motors The advantages of the wound rotor (Slip ring) Induction motors compared with the squirrel-cage motors are given below (i) They have very high starting torque (ii) They have very low starting current (iii) They have a means of varying speed by use of external rotor resistance. Read More: Thanks for Reading Please leave your comments below.

Table of Contents • • • • • • • Fig.1 Squirrel Cage rotor • In Squirrel cage induction motors the rotor is simplest and most rugged in construction. • Cylindrical laminated core rotor with heavy bars of copper or Aluminum is used for conductors. • Rotor conductors or rotor bars are short-circuited with end rings. Muzika fakira iz nu pogodi. • Rotor bars are permanently short-circuited and hence it is not possible to connect an external resistance in the circuit in series with the rotor conductors. • It has low cost. • There are no moving contacts in the rotor. • Higher efficiency.

• Low starting torque. It has 1.5-time full load torque. • Speed control by rotor resistance is not possible. • Starting current is 5 to 7 times the full load current.

What are the advantages of skewing of rotor conductors in Squirrel cage induction motor? Skewing is the tilting of rotor conductor bars as shown in Fig.1. The advantages of skewing are as follows • There is a production of uniform torque.

Due to this noise during operation reduces. • The magnetic locking tendency of the rotor reduces. During locking process, the stator and rotor teeth attract each other due to magnetic action. This locking process is called as Cogging. To avoid magnetic locking due to cogging, thats why conductors are skewed. Note: Number of Poles and phases develop automatically in cage rotor and equal to number of Poles and phases as in stator.